电话:4000-666-226

邮箱:sales@famouset.com

Launch of Electrical Lubricant Test Rig

Electric vehicle lubricants or e-fluids/greases must comply with more specifications compared to the conventional fluids/greases used in IC engine. A new generation of component test rigs relevant to fully electric vehicles (EV’s) have become essential for lubricants industry where most of its R&D spending is to compete and create value in EV’s market space. In this regard the Society of Tribology and Lubrication Engineers or STLE has organized an event (EV Conference) that gathers industrial and academic experts to share their views and experience on EV tribology.

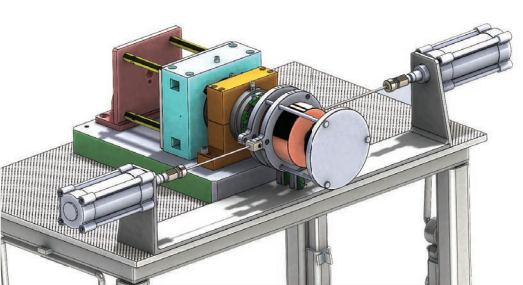

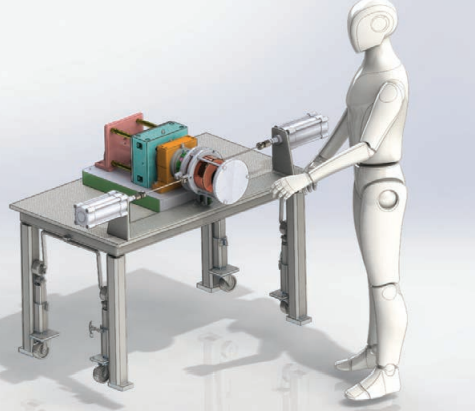

Ducom Instruments has invested in a new line of Electrical Lubricant Test Rigs (ELT's) that can address all the critical test parameters required for qualifying fluids and greases used in lubricating electric drive train components. When STLE EV committee approached us to share our views on ELTs, we got excited and to honor their request we planned to launch our High Speed Bearing Test Rig (see Figure 1) - a key product within Ducom ELT's.

On Friday 5th November (session 5: Lubricant Testing for EVs), we will present our innovative product design of two stage lubricated bearings that can be tested up to 30,000 rpm and at load up to 15 kN. Bearings can be lubricated with grease or oils, that can be heated up to 150 °C using our proprietary heat exchanger. Rotor dynamics and cooling system are key techniques to reduce its downtime and improve safety of the operator.

Electrical Lubricants Test Rig is the first in market that is aimed at creating high value lubricants for better performance of EV’s and empower the idea of reducing carbon emission through electrification.

We will elaborate on those techniques during the presentation. Each bearing station is embedded with smart sensors that capture the vibration, noise, bearing friction and temperature of the lubricated system. The sensor system is MOOHA-enabled: it completely automates the process of data collection, cloud storage, analytics, and reporting. Collectively they provide insight to e-grease or e-fluid performance (i.e. antiwear, thermal conductivity, friction and fatigue resistance). In the presentation, we will share a case study that describes the performance of few electrical lubricants that are widely used in electric motor and wheel hubs of battery-powered EV’s.

E-Fluid电动汽车润滑试验台

与IC发动机中使用的常规流体/油脂相比,电动汽车润滑油或电子流体/油脂必须符合更多的规范。新一代与全电动汽车(EV)相关的零部件测试平台已成为润滑油行业的重要组成部分,该行业的大部分研发支出都是为了在电动汽车市场上竞争并创造价值。在这方面,摩擦学与润滑工程师协会(STLE)组织了一场活动(EV Conference),聚集了行业和学术界的专家,分享他们在电动汽车摩擦学方面的观点和经验。

针对集成式电驱系统推出的专用润滑油,它不仅具备常规润滑油的功能,而且还具备良好的绝缘性能以保护驱动箱内的电路系统,同时还要兼具为电机散热以及确保电路导线不被腐蚀等功效。显然相比传统的润滑油,对于电驱系统的润滑油具备更高的技术壁垒。为了保证油品的纯净性,电动汽车采用了以天然气为原料转化的基础油,相比石油裂化的产品,几乎没有杂质,因此油液从外观上来看,几乎同纯净水无异。

Ducom Instruments公司投资开发了一种新的电气润滑测试设备(ELT’s),该设备可以满足润滑电气传动系统部件所需的流体和润滑脂的所有关键参数的测试要求。当STLE电动汽车委员会找到我们分享我们对电动轴承的看法时,我们很兴奋,为了满足他们的要求,我们计划推出我们的高速轴承试验台(见图1)——这是Ducom电动汽车试验台的关键产品。

我们的创新产品设计:两级润滑轴承,可测试最高30,000 rpm和最高15 kN的负载。轴承可以用润滑脂或油润滑,使用我们专有的热交换器可以加热到150°C。转子动力学和冷却系统是减少转子停机时间、提高操作人员安全性的关键技术。

本套电动润滑油试验台是市场上第一个旨在创造高价值的润滑油,以提高电动汽车的性能,并实现通过电气化减少碳排放的理念。

产品的设计加入了这些技巧。每个轴承站都嵌入了智能传感器,捕捉振动、噪音、轴承摩擦和润滑系统的温度。传感器系统支持mooha:它完全自动化了数据收集、云存储、分析和报告的过程。总体而言,它们提供了对电子润滑脂或电子流体性能(即抗磨、导热、摩擦和抗疲劳)的洞察。